By Manufacturing Processes

Solution for Film

CJ Biomaterial offers 5 compound grades which are compounded resins based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for Film applications. These grades are environmentally friendly semi-crystalline biopolymer compounds that improve functional performance and enable faster composting relative to PLA. The films made of PHACT compounds have superior sealability, flexibility, and less noise compared to PLA-only films. Final products made of PHACT compounds have faster rates of biodegradability than PLA-only films.

■ PHACT™ CA1270P

Designed for blown and cast film, may also be used in biaxially-oriented film

■ PHACT™ CA1240PF

An opaque film designed foe blown and cast film, may also be used in biaxially-oriented film

■ PHACT™ CA8270P-B1

Designed for biaxially-oriented film

*Currently available only for APAC Region

Features

- 100% bio content

- FDA approved for food contact

- Accelerates PLA degradation

- Colorable and printable

- Enhanced properties relative to PLA:

- Increased flexibility and softness

- Less noisy

- Enhanced oil and water resistance

Solution for Thermoforming

CJ Biomaterials offers 3 compound grades that are compounded resins based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for thermoforming process. These grades are environmentally friendly semi-crystalline biopolymer compounds that improve functional performance and enable faster composting relative to PLA. The addition of aPHA to PLA increases flexibility and impact strength, limiting breakage during production and distribution. These blends can also improve productivity during the thermoforming process. These compounds can reduce the thickness of final products by 12-15% compared to PLA, resulting in cost savings.

■ PHACT™ CA1680P

Suitable for semi-transparent applications

*Currently available only for APAC Region

■ PHACT™ CA1690P

The most transparent aPHA content than other grades

*Currently available only for APAC Region

Features:

- 100% bio content

- FDA-approved for food contact

- Industrial compostable

- High stability during distribution and storage

- Relative to PLA:

- Increased flexibility and impact strength

- Improved processability and productivity

- Reduction of the total input

Solution for Injection molding

CJ Biomaterial offer 2 compound grades which are compounded resins based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for Injection molding applications. These grades are environmentally friendly semi-crystalline biopolymer compounds that improve functional performance and enable faster composting relative to PLA. The addition of aPHA to PLA increases flexibility and impact strength and enhances water/oil resistance. These compounds also improve process ability during injection molding, allowing greater design flexibility. The mold shrinkage of these grades is similar to that of ABS, thus the existing molds for ABS can be used.

IM

■ PHACT™ CA1180P

Ideal for Cosmetic or food & beverage applications

*Currently available only for APAC Region

ISBM

■ PHACT™ CA1670P

An Opaque grade with low-temperature stability.

*Currently available only for APAC Region

■ PHACT™ CA1680P

Suitable for semi-transparent application.

*Currently available only for APAC Region

Features

- 100% bio content

- Industrial compostable

- High-gloss surface

- Colorable and printable

- FDA approved for food contact

- Enhanced properties relative to PLA:

- Increased flexibility and impact strength

- Improved processability

- Enhanced oil and water resistance

Solution for Fibers and Nonwovens

CJ Biomaterial offer 2 compound grades which are compounded resins based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for Fiber and Nonwoven applications. These grades can be used for a broad range of fiber, textile and nonwoven applications. Both grades are suitable for conventional fiber spinning and drawing processes. Fibers made with PHACT grades have excellent texture and softness compared to PLA alone. Converters can produce fibers at lower temperatures than PLA, enhancing processability and reducing costs. Final products made from our grades have better biodegradability relative to PLA fibers.

■ PHACT™ CA8370P

Ideal for nonwoven applications such as spun bond, staple fiber, etc

*Currently available only for APAC Region

■ PHACT™ CA8770P

Ideal for nonwoven applications such as spun bond, melt blown.

*Currently available only for APAC Region

Features

- 100% bio content

- Industrial compostable

- Enhanced spinning productivity

- FDA-approved for food contact

- Enhanced properties relative to PLA:

- Increased flexibility and softness

- Better dyeability (color expression)

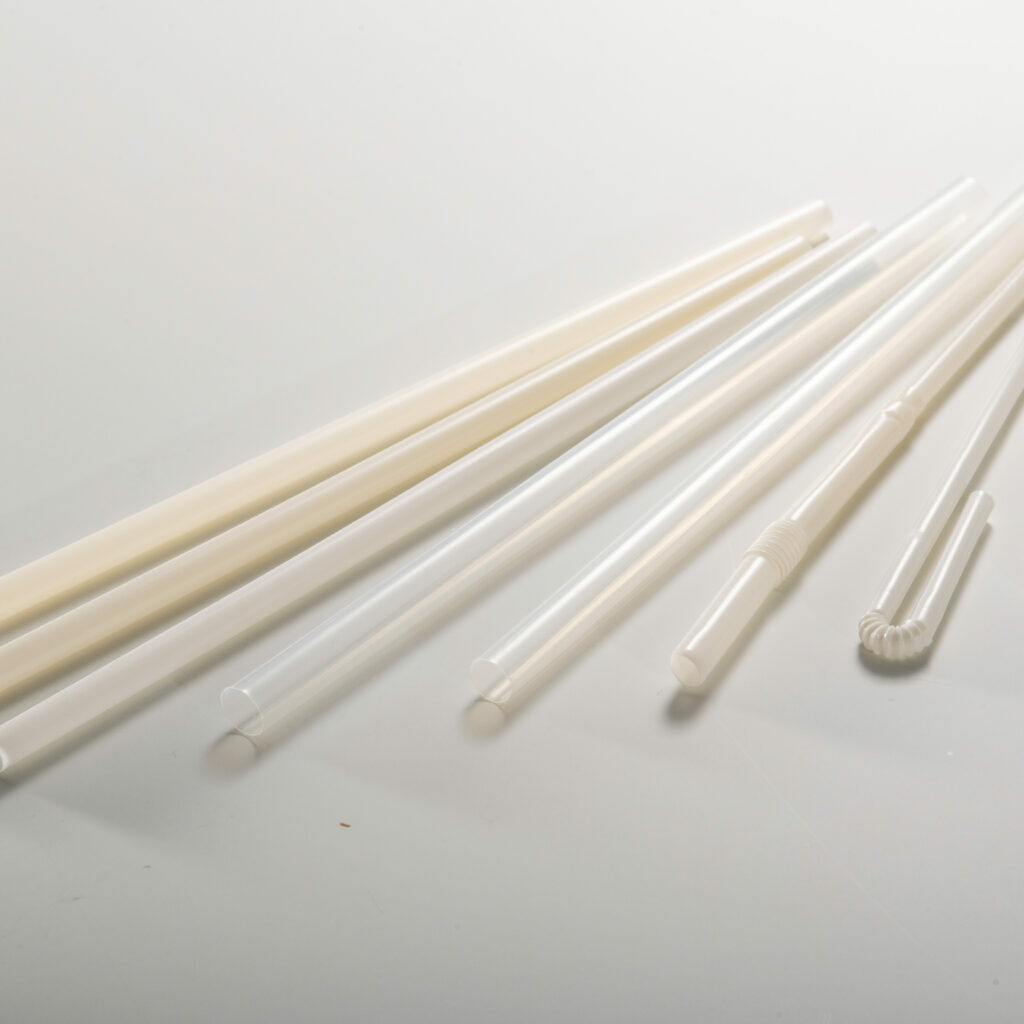

Solution for Extrusion (Straw)

CJ Biomaterials offers a compound grade which is a compounded resin based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for Straw application. The grade is an environmentally friendly semi-crystalline biopolymer compound that improves functional performance and enables faster composting relative to PLA. The addition of aPHA to PLA increases flexibility and impact strength and is ideal for straw applications.

■ PHACT™ CA8470P-S2

designed for straws in diverse shapes like flexible, telescopic straws, etc.

*Currently available only for APAC Region

Features

- 100% bio content

- FDA approved for food contact

- Industrial compostable

- Enhanced properties relative to PLA Straws:

- Increased processability into diverse shapes and functions

- Increased flexibility and resilience

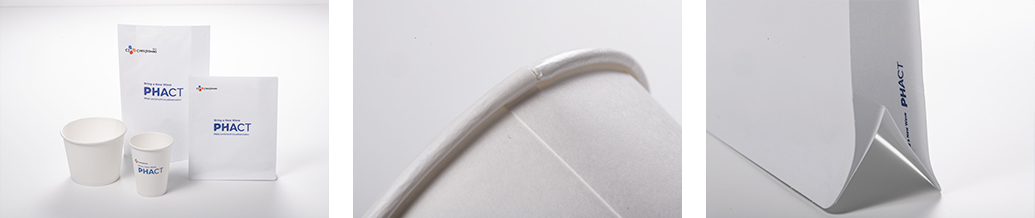

Solution for Paper Coatings

CJ Biomaterials offers a compound grade which is a compounded resin based on PLA (polylactic acid) and aPHA (PHACT™ A1000P) for Paper Coating application. The grade is a 100% bio-based and environmentally friendly semi-crystalline biopolymer compound which improves functional performance and has excellent biodegradability in home and soil compost conditions. It allows the production of compostable paper products depending on the grade of paper used. The grade has good temperature stability from cold storage to microwave systems and offers very high production efficiency.

■ PHACT™ CA8570P

Designed for paper coatings in food container and flexible packaging

*Currently available only for APAC Region

Features

- 100% bio content

- Enables home compostability

- Good temperature stability (-15°C to 100°C)

- Good water resistance

- FDA-approved for food contact

- Enhanced properties relative to PLA:

- Increased flexibility and impact strength

- Increased production efficiency