PHA process

Revolutionizing Sustainable Biopolymer Production

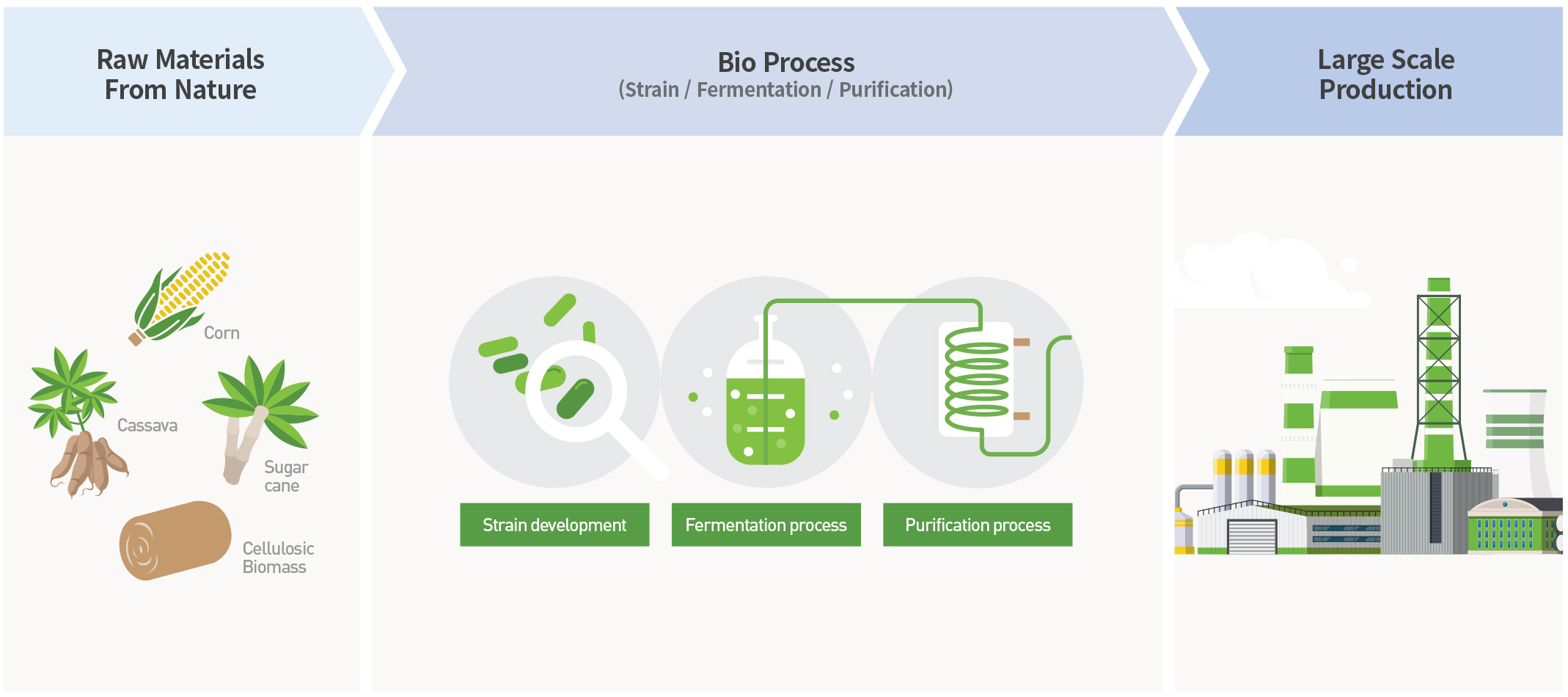

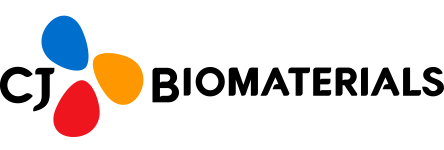

Many bacteria produce and use polyhydroxyalkanoates (PHAs) as an energy storage material in nature. CJ Biomaterials’ PHAs are produced through aerobic fermentation, converting natural sugars into PHA polymers directly inside microbial bio-factories. Standard stirred, aerated fermentation tanks are used. Each fermentation consists of a growth phase, during which empty cells (the "bio-factories") are grown to target concentrations, followed by a production phase, during which the cells fill up with PHA.

Our expertise allows us to increase PHA content in microorganisms from about a 5% default accumulation up to 85% through fermentation via engineered microbial strains. We employ advanced downstream technology for the extraction of PHA components and the manufacture of specific products.

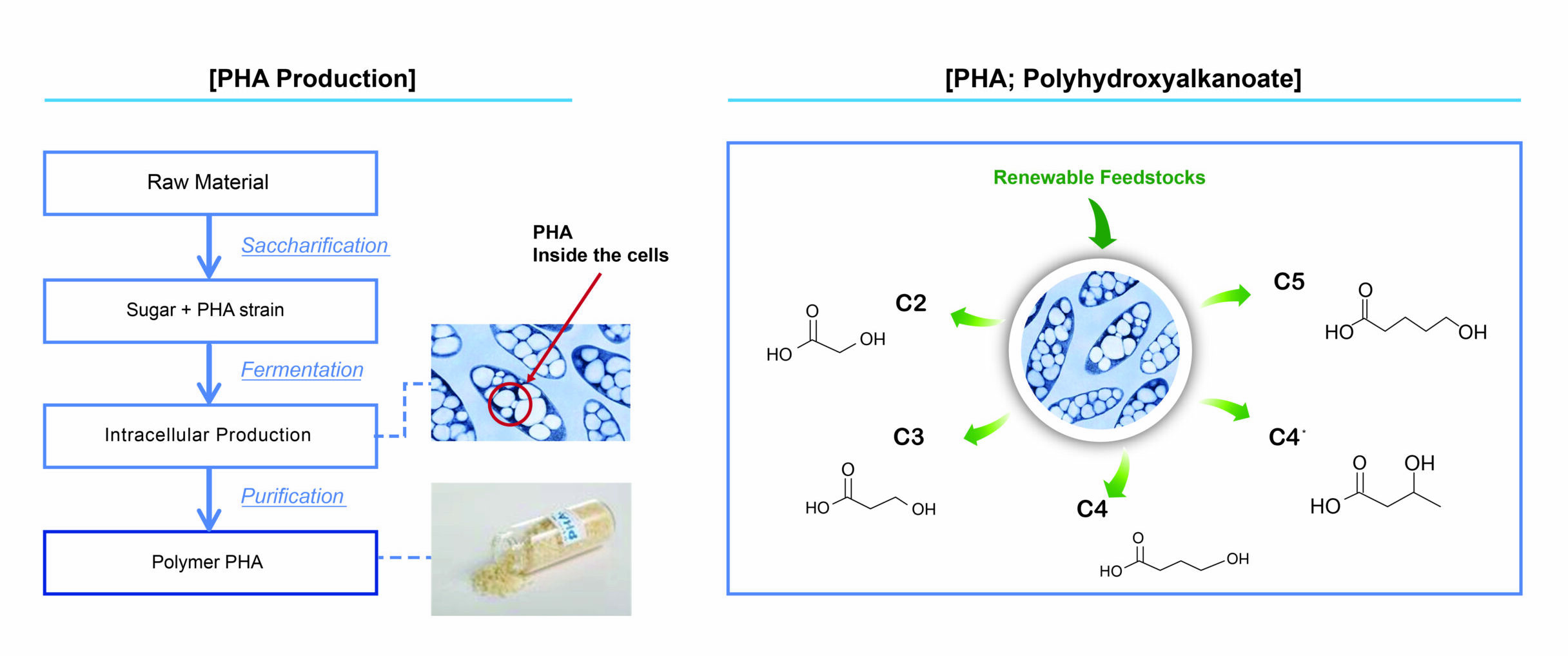

Creating tunable solutions

The CJ Biomaterials PHA technology platform is broad and differentiated. We an produce crystalline, semi-crystalline and amorphous PHAs by modifying the P3HB and P4HB ratios of our materials. An incredibly broad range of PHA polymers is made possible by this co-monomer ratio control.

Commercial production

50+ years of bio-synthetic technology and mass-production know-how is one of our core competencies. Our feedstocks can be bio-based sugars derived from sugarcane or corn. Now, CJ Biomaterials manufactures PHAs at our facilities in Pasuruan.