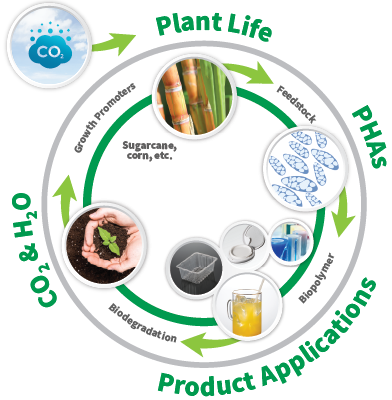

Circular Economy

Driving the Circular Economy with Advanced PHA Solutions

At CJ Biomaterials we use innovation to help people live better lives,

while ensuring the future of our planet.

A circular economy is a model of production and consumption that involves reusing, repairing, refurbishing and recycling existing materials and products for as long as possible in a way that limits our reliance on precious natural resources. As Antoine Laruent de Lavoiser explained, ‘nothing is lost, everything is transformed’. A circular economy is restorative and regenerative. It cuts waste, lowers CO2 emissions and uses less of the world’s finite resources. It focuses on meeting the needs of our growing global population but in a sustainable way.

At CJ Biomaterials, we find our role in helping create a circular economy through innovative technology. We develop biopolymers in a sustainable way. These biopolymers are biodegradable and home compostable – offering end-of-life options that don’t require specialized technology. We invent ways to deploy them to help reduce plastic waste – but also help make better products that better meet people’s needs.

Creating a circular economy will require all of us – raw material suppliers, processors, manufacturers, product designers, brand owners and everyday people – to work together. When we do this, we can address almost every pressing global environmental issue. Climate change. Plastic waste. Water, air and land environmental quality.

How do PHACT™ PHAs support a circular economy?

CJ Biomaterials' PHACT polyhydroxyalkanoates (PHA) have raw material inputs from renewable materials. Our manufacturing processes and products are environmentally friendly and we work on ways to help put these products into use addressing a highly competitive commercial environment.

The raw materials for PHACT are sourced from plants like sugar cane, tapioca, corn and cellulosic biomass. CJ Biomaterials can increase PHA content in microorganisms from about 5% default accumulation up to 85% through fermentation via engineered microbial strains. With advanced technology, PHA is extracted and manufactured into usable forms for processing. These PHA products can be compounded and processed using conventional plastics processing equipment. They can also be used as modifiers to other polymers or biopolymers to increase bio-based content, accelerate biodegradation and improve functional properties of resins and finished products. At the end of life, they go back to nature through various paths.

Sustainable biopolymer solutions for a circular economy

The mission of CJ Biomaterials' business is to develop meaningful, sustainable solutions that can help reduce and replace fossil fuel-based technologies. Being sourced from renewable material that can be responsibly disposed of after use, PHA makes it possible for industries to develop a truly circular solution.