Masterbatches

Advanced Masterbatches: Seamless Integration, Maximum Impact

CJ Biomaterials offers masterbatch products to help processing challenges for biopolymers. Our masterbatch product is supplied in concentrated pellet form of amorphous polyhydroxyalkanoate (aPHA), blending other biopolymers. It can be directly added as dry-blended during the conversion process. Depending on the customer's preference, the blending ratio can be adjusted in various ways. It is also easier to handle than PHA neat resin in an extruder.

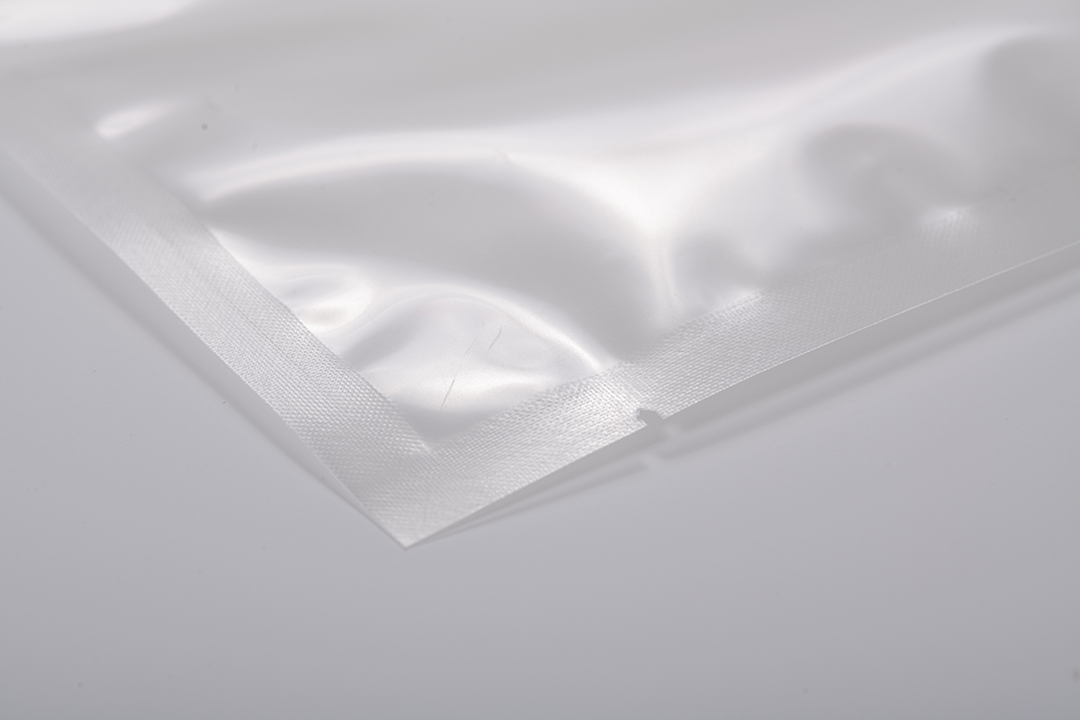

PHACT MA1250P and PHACT MA1250P-A are masterbatch products that are composed of polylactic acid (PLA) and aPHA known as PHACT A1000P. PHACT MA1250P contains 45% aPHA and is easier to handle than aPHA neat resin. PHACT MA1250P can be added as a dry blend during the conversion of PLA-based products. Customization of the PHACT MA1250P blending ratio is easily accomplished.

PHACT MA1250P-A is ideally used in seal layers of multi-layered film products. The high concentration of aPHA increases the flexibility of compounding and blending materials. It also accelerates the degradation of PLA, improving industrial compost response.

Features

- 100% bio content

- FDA-approved for food contact

- Good seal performance

- Enhanced tear propagation resistance

- Improves impact strength

- Improves flexibility and film-handling capability of PLA

- Maintains the clarity of PLA

Test Our Eco-Friendly Masterbatches

Request a sample to see how our masterbatches can enhance your applications.